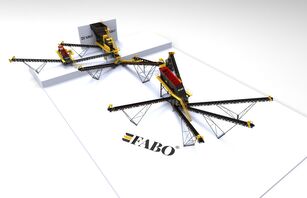

New FABO VSI-700 VERTICAL SHAFT IMPACT CRUSHER | SAND MACHINE 150 TPH crushing plant

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Turkey

Turkey

*Installation and Operator Training FREE

VSI machines are used to obtain fine sand and fine gravel from the hardest with a high degree of abrasive materials such as basalt, granite, gabbro, riverstone etc.

This type of crushers acting as tertiary crushers in facilities with with it’s high cubic ratio and fine product.

These high-speed crushers are manufactured in two different combinations as open rotor and closed rotor. Vertical shaft impact crushers (VSI) are designed with a unique rock-on-rock crushing principle, which significantly reduces the wear costs while offering superior cubical shape for the best quality fine aggregate production. The fact that it reduce their service requirements and times, and to increase their crushing performance with their low investment costs.

General Specifitions and Futures:

- Fine product, low wear cost, cubic shape, application flexibility and maintainability.

- Rotor and crushing chute with stress relieved welding

- Inner surfaces of the crusher is coated with wear resistant lining plates

- Hydraulic opening cap

-Automatic Lubrication system

• Model: FABO VSI-700

• Type: Vertical Shaft Impact Crusher Closed rotor

• Capacity: 100-150 tph

• Max Feeding: 30 mm

• Rotor Size: Ø 700 mm

• Speed: 50-70 m/s

• Motor: Heavy duty GAMAK, 200 kW Bearings: Heavy duty SKF-FAG

• Weight: 10000 kg

• Dimensions: 4000 * 3000 * 2450 mm

• Including chassis, motor and safety guards.

FOR FURTHER INFORMATION PLEASE FEEL FREE TO CALL US!!!

* Formation d'installation et d'opérateur gratuit

Les concasseurs VSI sont utilisés pour extraire le sable fin et le gravier fin des matériaux les plus durs avec un degré élevé d'abrasifs, tels que le basalte, le granit, le gabbro, la pierre de rivière, etc. produit idéal.Ces concasseurs à grande vitesse sont fabriqués en deux combinaisons différentes: rotor ouvert et rotor fermé.Les concasseurs à percussion à arbre vertical (VSI) sont conçus selon le principe unique de broyage rock-on-rock, qui réduit considérablement les coûts d'usure offrant une forme cubique supérieure pour la meilleure qualité de production d'agrégats fi ns. Le fait qu’il réduise leurs exigences et délais de service et augmente leurs performances de concassage avec leurs faibles coûts d’investissement.

Générale Et Future Spécification

- Produit fin, faible coût d'usure, forme cubique, flexibilité d'application et maintenabilité.

- Goulotte de rotor et de broyage avec soudure allégée

- Les surfaces intérieures du concasseur sont revêtues de plaques de revêtement résistantes à l'usure

- Bouchon d'ouverture hydraulique

- Système de lubrification automatique

• Modèle: FABO VSI-700

• Type: Concasseur à percussion à axe vertical à rotor fermé

• Capacite: 100-150 tph

• Max alimentation: 30 mm

• Taille du rotor: Ø 700 mm

• Vitesse: 50-70 m / s

• Moteur: GAMAK robuste, 200 kW. Roulements: SKF-FAG robuste

• Poids: 10000 kg

• Dimensions: 4000 * 3000 * 2450 mm

• Y compris châssis, moteur et protections.

POUR PLUS D'INFORMATİONS S'IL VOUS PLAÎT N'HESITEZ PAS A NOUS APPELER!

• Наши установки гарантируются компанией на 1 год!

• Установка и пользовательское обучение бесплатно!

Ударные дробилки с вертикальным валом применяются в качестве третичных дробилок в комплексах с высоким объемом среднефракционного материала для получения мелко-песочного продукта и гравия посредством дробления твердых и абразивных материалов.

Эти дробилки с высоким числом оборотов, производятся в двух комбинациях: открытый ротор и закрытый ротор. Роторная дробилка характеризуется тем, что процесс дробления материала, подаваемого через питатель дробилки, осуществляется по принципу удара камнем о камень, что происходит при помощи ротора, вращающегося на высокой скорости. И, в виду того, что дробление происходит в результате столкновения камня с камнем, себестоимость расходных материалов весьма экономична. Ударная дробилка с вертикальным валом является третичной дробилкой с низкой эксплуатационной себестоимостью.

Общие характеристики и преимущества:

- Чистый и монофракционный продукт, низкая стоимость износных частиц, легкость обслуживания и ремонта.

- Ротор и дробильный желоб со сниженным напряжением сварки

- Внутренние поверхности дробилки покрыты износостойкими облицовочными пластинами

- Гидравлическая раскрывающийся корпус

- Автоматическая система смазки

• Модель: FABO VSI-700

• Тип: Ударная дробилка с вертикальным валом (Закрытый ротор)

• Производительность: 100-150 т / ч

• Максимальная подача: 30 мм

• Размер ротора: Ø 700 мм

• Скорость: 50-70 м / с

• Двигатель: сверхмощный GAMAK, 200 кВт.

• Подшипники: Высокопрочный SKF-FAG.

• Вес: 10000 кг

• Размеры: 4000 X 3000 X 2450 мм

• Включает в себя шасси, мотор и защитный корпус.

ДЛЯ ПОДРОБНОЙ ДЕТАЛИ СВЯЖИТЕСЬ С НАМИ!

Bu tip kırıcılar, yüksek kübik oranı ve ince ürün ile tesislerde üçüncül kırıcı olarak görev yapar.

Bu yüksek hızlı kırıcılar, açık rotor ve kapalı rotor olmak üzere iki farklı kombinasyonda üretilir. Dik Milli Kırıcı (VSI), en iyi kalitede ince agrega üretimi için üstün kübik şekil sunarken aşınma maliyetlerini önemli ölçüde azaltan benzersiz bir taş taşa kırma prensibi ile tasarlanmıştır. Servis gereksinimlerini ve sürelerini azaltması ve düşük yatırım maliyetleri ile kırma performanslarını arttırır.

Genel Özellikler ve Gelecekler:

- İnce ürün, düşük aşınma maliyeti, kübik şekil, uygulama esnekliği ve bakım kolaylığı.

- Gerilim giderilmiş kaynaklı rotor ve kırma oluğu

- Kırıcının iç yüzeyleri aşınmaya dayanıklı astar plakalarıyla kaplanmıştır

- Hidrolik açılan kapak

- Otomatik Yağlama sistemi

• Model: FABO VSI-700

• Tip: Dik Milli Kırıcı

• Kapasite: 100-150 tph

• Maksimum Besleme: 30 mm

• Rotor Boyutu: Ø 700 mm

• Hız: 50-70 m/s

• Motor: Ağır hizmet tipi GAMAK, 200 kW

• Rulmanlar: Ağır hizmet tipi SKF-FAG

• Ağırlık: 10000 kg

• Boyutlar: 4000 * 3000 * 2450 mm

• Şasi, motor ve güvenlik korumaları dahil.

*Tüm ürünlerimiz 1 yıl garantilidir!

*Kurulum ve Operatör Eğitimi ÜCRETSİZ

DAHA FAZLA BİLGİ İÇİN LÜTFEN BİZİ ARAYIN!!!